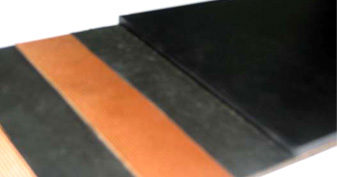

Structure:

- Top Cover Rubber

The top cover is made of special rubber compound to cover the inner reinforcing layers of a conveyor belt. Top cover is usually thicker than the bottom cover and can be made as flatbed or chevron. If the material to be conveyed is sharp (e.g. glass pieces, rocks, minerals, grains, etc.), the appropriate thickness of the top cover will also help extend the usage life of the conveyor belt.

2. Skim Coat Rubber

A special rubber compound that works like a glue coated on the reinforcing fabric to help strengthening the bonding between the inner rubber and cover rubber.

3. EP Fabric (Carcass)

The reinforcing layer made of polyester fabric that gives high tensile strength and also flexible enough to support the conveying materials. There are several specifications of polyester fabric depending on the size of the thread. The bigger the thread, the higher tensile strength it can support.

4. Bottom Cover Rubber

The same as top cover rubber but usually thinner because it was not designed to receive any impact from the material as the top cover.

** The rubber compound for the top and bottom cover has many grades. Each grade is suitable for a particular material and working environment. You can find more detail in the product section, or contact us for more information.

Thickness:

|

Number of ply |

Top cover (mm) |

Bottom cover (mm) |

Total (mm) |

|

2 |

2.5 |

1.5 |

6 |

|

3 |

2.5 |

1.5 |

7 |

|

4 |

3.5 |

1.5 |

9 |

|

5 |

3.5 |

1.5 |

10 |

|

6 |

4 |

2 |

12 |

Weight:

|

Total thickness (mm) |

Weight (kg) |

|

6 |

7.8 |

|

7 |

9.1 |

|

8 |

10.4 |

|

9 |

11.7 |

|

10 |

13 |

|

11 |

14.3 |

|

12 |

15.6 |

.jpg)