Conveyor frame is the system using the motor to pull the conveyor belts move. Thus, the materials are convey in the short or long distance with heavyweight.

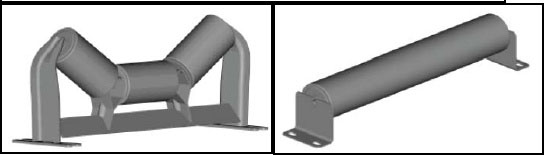

- Rollers in the frame:

They are divided into 2 types: coaster rollers for the flat conveyor belts and for the concave conveyor belts.

- The coaster rollers for the flat conveyor belts: are design in flat shape, help to keep the conveyor belts always straight throughout conveying.

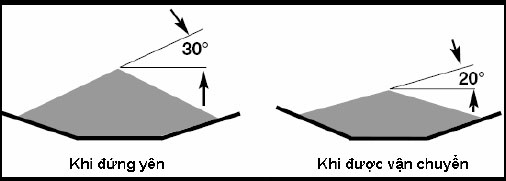

- The coaster rollers for the concave conveyor belts: which are set in slope position, so when installed they will create the concave for the belts. The degree of the slope will depend on the characteristics of the materials’ characteristics.

In particular, the steep degree will be changed slightly. For example, the slope degree when standing stable is 30o, but when moving, 2 sides will be washed out which made the degree now only 20o.

The following table estimated the minimum width of the conveyor belts compare to the sizes of the materials to eliminate the ability of falling materials outside or making the conveyor belts tear.

|

Minimum width (mm) |

Materials’ sizes (mm) |

|

|

The same |

Different (The largest one must be not larger than 10% of the whole volume) |

|

|

400 |

64 |

100 |

|

450 |

75 |

125 |

|

500 |

85 |

150 |

|

600 |

110 |

200 |

|

650 |

125 |

225 |

|

750 |

145 |

275 |

|

800 |

157 |

300 |

|

900 |

180 |

350 |

|

1000 |

203 |

400 |

|

1050 |

215 |

425 |

|

1200 |

250 |

500 |

|

1400 |

297 |

600 |

|

1600 |

345 |

700 |

|

1800 |

380 |

800 |

|

2000 |

440 |

900 |

|

2200 |

500 |

1000 |

|

2400 |

550 |

1100 |

|

2600 |

600 |

1200 |

|

2800 |

650 |

1300 |

|

3000 |

700 |

1400 |

|

3150 |

750 |

1500 |

Bach Tung JSC supply the conveyor belts, rollers, and services of processing conveyor belts, rollers, the frame based on customization.

.jpg)