The rollers are applied popularly in the conveying system of the companies, factories belong the different industries, agricultures. They are smaller than rulo.

Most rollers are used to support the conveyor belts’ move.

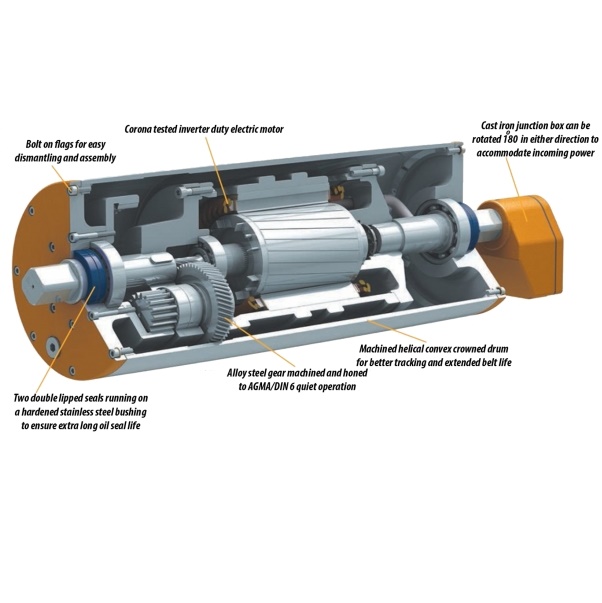

In term of active rollers:

They are distinguished with the passive roller based on their operating mechanism. In detail, the active rollers perfrom separately and do not depend on or be impacted by the outside forces. They work based on the pulling motor, curoa belts or pulling chain, or mini motor which are added inside. Otherwise, the passive rollers perform based on the pushing force when conveying the materials, or the effected force that the conveyor betls apply on.

Detail structure:

- Core: are processed two sides, side grip or taro; If used with belt conveyor systems, the two sides are cut

- Tubes: usually made from iron, or steel, inox, ... and need to processed to fit the holes to the bearing.

- Bearings: easy to be weared, beared strong friction. So now there are many types of bearings with different qualities in the market

- Clasp: divered quality

- For some types of rollers such as: plastic rollers, reducing vibrant rollers, etc. are cover by the rubber to reduce friction and impacts as well as increase elasticity.

Bach Tung JSC specialized in directly importing conveyor belts and rollers from Japan, Thailand, Germany, etc. They are processed at the factory or the staffs will come to the customers’ factories to perform glue, or heat compression and install the conveyor belts.

.jpg)